Speedy Surfaces

Researchers from the Max Planck Institute for Polymer Research in Mainz, Germany, and the Tampere University of Technology, Finland, have found a new way of applying a structured coating for liquid repellency.

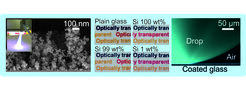

Researchers from the Max Planck Institute for Polymer Research in Mainz, Germany, and the Tampere University of Technology, Finland, have found a new way of applying a structured coating for liquid repellency. By using liquid flame spray, the method is extremely fast. Not only water but also oil drops do not adhere to these surfaces but remain spherical and bounce or roll off easily.

Potential applications of surfaces that are super liquid-repellent range from protective and self-cleaning textiles, goggles and windows for medical devices and gas exchange membranes. Applications of liquid-repellent coatings depend not only on their wetting properties, but also on their transparency, robustness, and fabrication cost and speed. Besides of being super-repellent against liquids, this new coating shows high transparency and withstands impacting high-velocity oil and water drops.

These extraordinary properties are based on a specific structure of the coating composed of nanometer-sized silicon dioxide–titanium dioxide particles. The method can be scaled up to coat large surface areas. Liquid flame spray is already used in industry to color glass and produce optical fibers. As the exposure time of the substrate to the flame is extremely short, even highly flammable materials like paper and wood can be coated.

The researchers have combined this fast and scalable processing method with the extraordinary liquid-repellent properties. They also discussed the criteria the coating needs to fulfill to achieve the superior liquid repellency. They described in detail how they managed to tune the coating morphology to meet these criteria. Their strategy can be widely applied to produce coatings composed of different materials because liquid flame spray can be used to synthesize a broad range of oxides, metal nanoparticles, and their mixtures.