Tailored tires: elucidating the molecular origin of strain hardening in polymer composites

Replacing the trial-and-error approach with a concept to independently tune linear and nonlinear mechanics in polymer composites – polymers with additional filler particles – scientists of the Max Planck Institute for Polymer Research (MPI-P) have shown how the amount of fillers sets the strain-hardening properties. The findings allow for a tailored design of materials, for example car tires, as they need to support cyclic and static loads.

Car tires are subject to a great variety of material stresses. Due to linear elasticity the tires resist small deformations, which ensures that they can bear small cyclic loads during driving. But tires also have to resist large deformations, such as impacts from driving over speedbumps and curbs. Consequently, it is also necessary to choose a formulation that satisfies nonlinear elastic properties.

How to design the car tires of the future?

Engineering such properties of composite polymer materials, especially the phenomenon of strain hardening, which refers to a material’s resistance or stiffness during straining, have been traditionally optimized through trial-and-error: the longstanding question has been about the relation of linear and nonlinear elastic properties to the amount and size of fillers in the individual constituents. In the journal Proceedings of the National Academy of Sciences of the United States, the research group led by Dr. Sapun Parekh, project leader at the MPI-P, has now demonstrated how composites’ elastic properties can be tuned precisely.

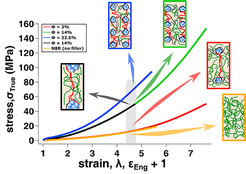

Dr. Parekh and his team used different methods to quantify the nanoparticles and polymer chain orientation in composites, among others transmission electron microscopy imaging and real-time molecular spectroscopy during mechanical deformation. Theoretical modelling techniques helped the scientists to interpret the experimental results. The scientists showed that nonlinear strain hardening in nanocomposites, mediated by polymer chain alignment, varies only with nanoparticle amount – and not size. This finding provides a rational plan for material design. With the nanoparticle amount, engineers can first design for nonlinear elasticity and then, using the appropriate nanoparticle size, for linear elasticity to achieve the desired properties in a directed approach.

What are composites?

Composites consist of different constituent materials: generally a flexible part, which is often soft and rubbery, and a reinforcing part that contains mostly inorganic material, such as glass because it is extremely hard and brittle. When blended together, the constituents form a so-called composite – with characteristics that are different from those of the individual components. These enhanced features can range between higher elasticity and conductivity, as well as lighter weight, while possibly being less expensive. Engineering the characteristics of composites depends on their later use. Commonly they are also deployed as bearing sealants in combustion engines and as aircraft body materials.