How Frost Forms and Grows on Lubricated Micro- and Nanostructured Surfaces

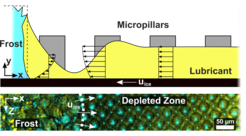

Currently, different strategies are explored to design surfaces which passively avoid, retard or repel frost. One representative of such a surface is the lubricant impregnated surface: The lubricant on a micro-/nanometric scaffold on the surface avoids sticking and easily removes contaminants such as frost. The dendritic frost structure, however, depletes the lubricant over time, leading to decay of the surface functionality. We rigorously investigate the frost to surface dynamics by powerful optical methods, such as confocal microscopy in moderately sub-zero temperatures (-12 °C to -22 °C). Formation and growth were micro- and mesoscopically recorded. The emerging flow of the lubricant within the surface microstructure towards the propagating frost was accurately resolved over time. We validated these findings by means of thin film models. The results matches excellently to the experimental findings. Quantifying the lubricant flow helped us to point out the two governing parameters of the depletion process, namely: (1) frost propagation speed and (2) frost dendrite morphology. These in-depth insights into the coupling between lubricant flow and frost formation/propagation enable an improved control over frosting by adjusting the design and features of the surface.